Articulated Front Loader

No exhaust odor: No diesel exhaust odor inside and outside the cab

Smoother and more precise operation: Electric drive and electronically controlled hydraulic systems provide faster response and more precise control, improving smoother operation and micro-control capabilities.

Low maintenance cost: The main maintenance is concentrated on the motor, electronic control system and battery. The workload and complexity of daily maintenance are greatly reduced, eliminating the need for regular replacement parts such as engine oil, oil filter, air filter, diesel filter, etc.

Articulated Front Loader Description

The core value of Articulated Front Loader lies in their significant comprehensive advantages: lower operating costs (the price difference between electricity and fuel plus reduced maintenance requirements), excellent environmental performance (zero tail gas emissions and low noise), excellent operating performance (instantaneous high torque, fast response and energy recovery capabilities) and improved operating comfort. Although the initial acquisition cost is high and is limited by the range and charging infrastructure, with the continuous advancement of battery technology, the continuous decline in costs, the active promotion of favorable policies and the increasingly improved charging network, electric loaders are showing great potential in more and more application scenarios with their strong competitiveness, and are undoubtedly the key force in promoting the green transformation of the construction machinery industry.

Reasonable pipeline layout: The pipeline layout is clear and reasonable, and maintenance is convenient

Wide cab vision: The cab has a wide field of vision, which not only improves operating comfort, but also improves operating efficiency and reduces operating risks in narrow areas.

Double-layer anti-slip pedal: provides double safety protection, effectively prevents slipping and stepping into the air, while improving the convenience of getting on and off.

One machine for multiple uses: Through the quick connector, one host can be equipped with different attachments such as snow shovel, bucket, fork, etc. to achieve different scenarios

| Rated load (kg) | 700 |

| Overall weight (kg) | 2100 |

| Bucket capacity (m³) | 0.25 |

| Maximum steering radius | ±45° |

| Maximum turning radius (mm) | 2200 |

| Amplitude of the rear axle | 19° |

| Total time (s) | 9 |

| Working time (h) | 6 |

Speed (km/h) | low speed 10 High way 20 |

| Dumping height (mm) | 2110 |

| Lifting height (mm) | 2527 |

| Overall dimension (mm) | 3974*1260*2250 |

| Dumping distance (mm) | 722 |

| Bucket width (mm) | 1130 |

| Wheel base (mm) | 1380 |

| Wheel tread (mm) | 945 |

| Ground clearance (mm) | 200 |

| Battery capacity (kw) | 14.4 |

| Rated voltage (v) | 72 |

| Charging time (h) | 8 |

| Electrical system voltage (v) | 12 |

| Type of steering hydraulic system | Full hydraulic steering |

| System pressure (mpa) | 14 |

| Voltage (v) | 72 |

| Power (kw) | 4*2 |

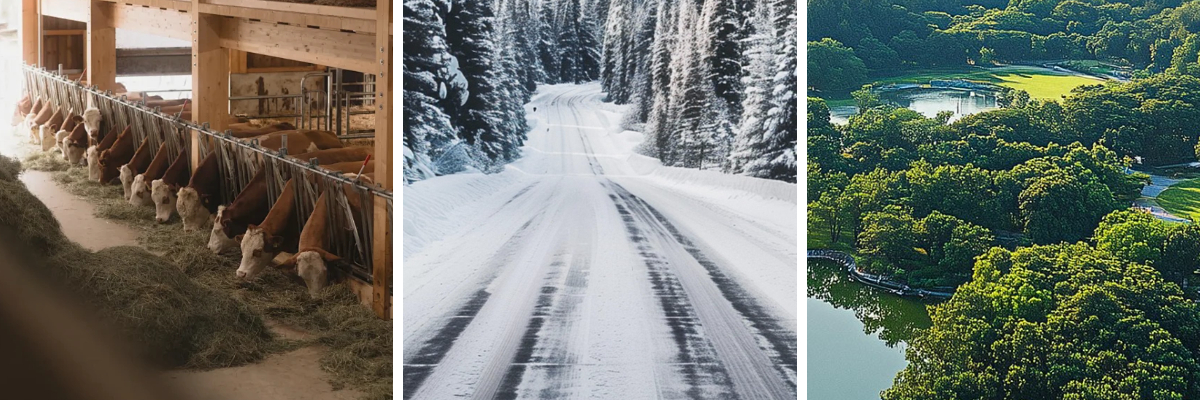

Agriculture and animal husbandry: handling feed, cleaning manure from animal sheds, loading grain. Handling organic substrates, fertilizers, agricultural products

Mines and quarries: loading blasted ore and gravel. Material transfer at crushing stations, screening stations and loading points. Material sorting and leveling.

Municipal Engineering and Environmental Sanitation: Carrying asphalt mixture, loading repair materials, and cleaning construction waste.

Carrying green soil, fertilizer, trees, and pruned branches and leaves. It can also be equipped with a snow shovel or snow bucket to remove snow in squares, factory areas, community roads and other areas.