Electric Forklift VS. Gas Forklift: Which Is The Best Solution For Warehousing And Logistics?

In the key decision of forklift selection, "Is an electric forklift better than a gas forklift?" is a question that many people will ask when purchasing. There is no so-called good or bad between the two. In the same field, they have their own strengths, not just right or wrong - electric forklifts have significant advantages in indoor operation, long-term cost and environmental protection, while gas forklifts are more reliable in large-load, high-intensity outdoor operations. The key to selection is to accurately match your specific needs.

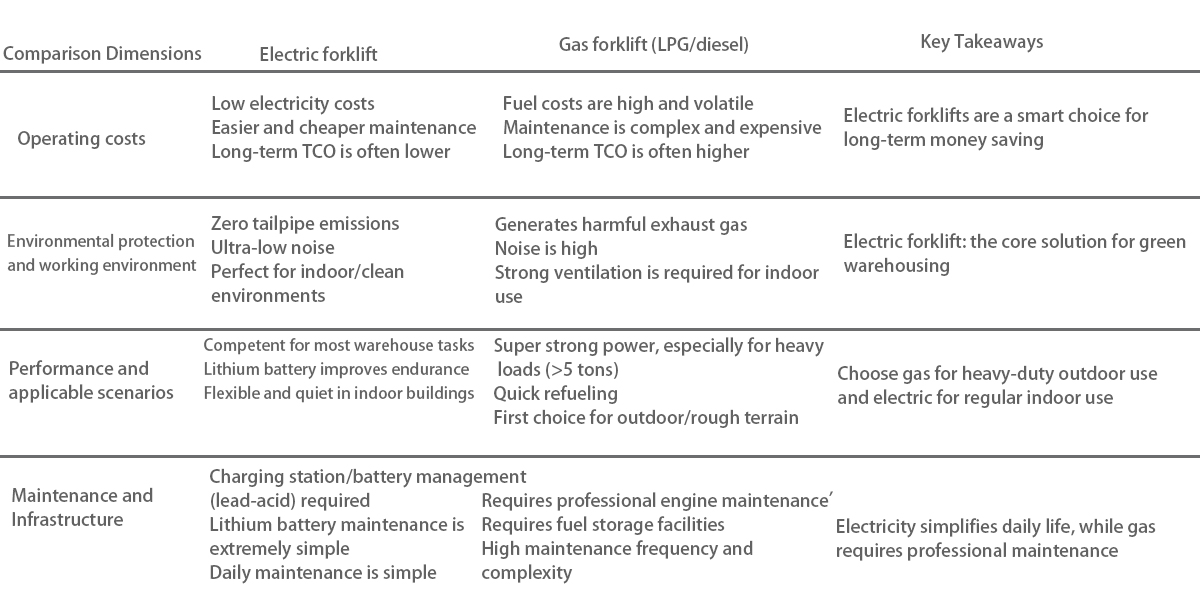

Differences between electric and gas forklifts

Operational costs: Electric forklifts are more cost-effective in the long run

Electric forklifts: Saving money is the core label of electric forklifts. The main cost is the relatively low cost of electricity charging, which is much lower than the continuous purchase of gas or diesel. Maintenance is also simple. There is no need to replace machine parts such as engine oil, spark plugs, and air filters. The total cost of ownership is usually significantly lower than that of gas forklifts, especially in high-usage scenarios.

Gas forklifts: Fuel costs are the bulk of its expenses, and they fluctuate with oil prices. Engine maintenance is required, and regular oil, filter, coolant, etc. are required. The maintenance cost is higher, and its cost will be higher than that of electric forklifts in the long run.

Environmental protection and working environment: Electric forklifts are a green and quiet choice

Electric forklifts: Zero exhaust emissions are the most significant feature, and are perfectly suitable for indoor environments with strict air quality requirements such as warehouses, cold storage, food and medicine workshops, etc. At the same time, the operating noise is extremely low, which greatly improves the working environment and enhances the comfort of employees.

Gas forklifts: The combustion process will inevitably produce harmful exhaust gas, and strong ventilation is required when using it. The use of warehouses, cold storage, food and medicine workshops, etc. is limited and there are safety hazards. The operating noise is also significantly louder, which may interfere with communication and affect employee health.

Performance and applicable scenarios: Gas forklifts are more powerful

Electric forklifts: Electric forklifts, especially those equipped with lithium-ion batteries, have greatly improved their performance and can meet the needs of most warehouse applications. However, traditional lead-acid batteries may face challenges in outdoor working conditions that require continuous high-intensity work.

Gas forklifts: More powerful, especially good at handling heavy loads and rugged outdoor sites. Gas refueling only takes a few minutes and can be used, suitable for long-term continuous operation or multi-shift scenarios, without waiting for charging.

Conclusion: How to make your wise choice?

If your operating environment is mainly indoors, the load demand is small and medium tonnage, and there is a place to charge in the operating environment, such as a warehouse, workshop, cold storage, and the environmental requirements are relatively high, and you hope to have lower expenses. You can choose an electric forklift.

If your operating environment is outdoors with good ventilation conditions, there are requirements for load, and the equipment needs to run at high intensity, the procurement budget is limited, and you don’t care so much about fuel costs, you can choose a gas forklift