Skid Steer Loader VS Wheel Loader: Choose The Right Equipment To Improve Work Efficiency

They are all called loaders, but some work on construction sites, some shuttle around warehouses, and some circle around in gardens. Are you wondering what the difference is between a skid steer loader and a wheel loader? As core material handling equipment, their design concepts and areas of expertise are very different. Understanding these differences is a key step in making accurate investments and maximizing production efficiency.

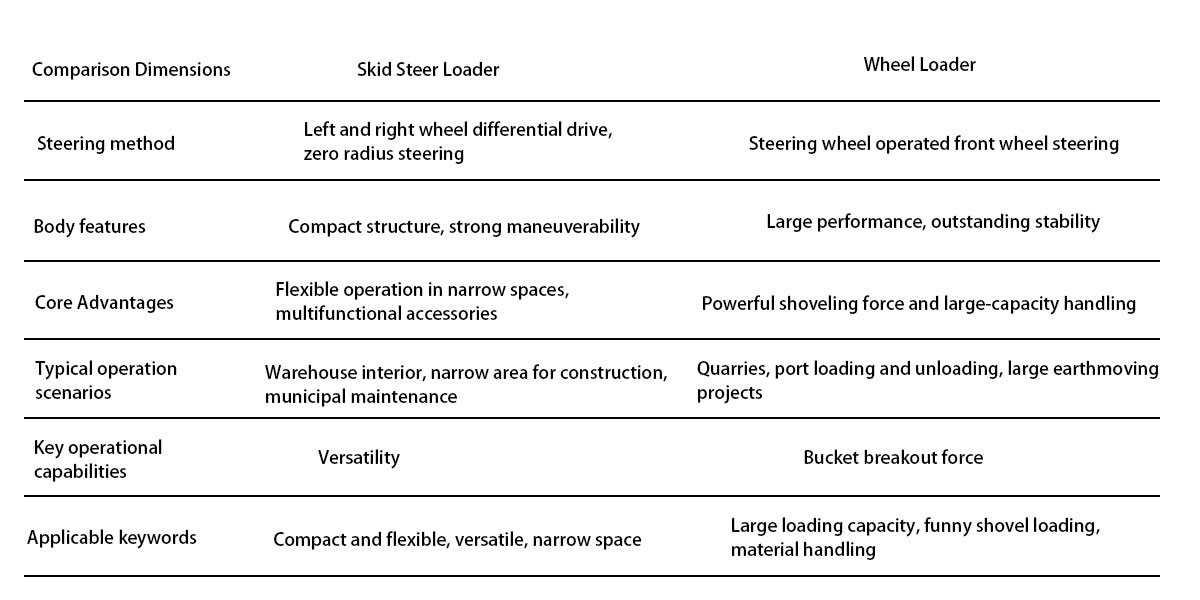

The core difference between a loader and a skid steer loader

Skid steer loader: It does not have a traditional steering wheel, and relies on the independent differential drive of the left and right wheels (or tracks) to achieve steering. Want to turn? Just let the wheels on both sides rotate at different speeds or even in opposite directions to achieve "zero radius" on-the-spot steering, which is the best in narrow spaces.

Wheel loader: The steering wheel is used to control the front wheel steering, just like a common car or truck. Its turning radius is relatively large, and more space is required to complete the turning action. The drive mode is usually four-wheel drive.

The difference between the two is also reflected in the workplace

Skid steer loader: mobility is its biggest trump card! Thanks to the zero-radius steering and compact body, it can flexibly shuttle and turn around in warehouse aisles, building interiors, equipment-intensive areas and other space-constrained areas, with amazing efficiency.

Wheel loader: It is usually larger and more powerful. Although the steering is not as flexible as the skid steer, its stability and powerful bucket digging force are irreplaceable in open construction sites, material yards, earthworks and other places that require large-scale movement and large loads.

There is also a big difference in the operating capabilities of the two.

Skid steer loader: By quickly replacing front-end attachments (such as forks, sweepers, drills, milling machines, snow blowers, etc.), a skid steer can switch roles instantly to meet the needs of diversified material handling and special operations. It is an ideal partner for comprehensive site maintenance, agriculture, and municipal administration.

Wheel loader: The core function is powerful and focused - efficient shoveling, handling, and unloading of bulk materials (such as sand, coal, and soil). Its large-capacity bucket and powerful lifting capacity are designed for heavy-duty shoveling. Although some attachments (such as forks) can also be replaced, its versatility and convenience of replacement are usually not as good as those of skid steers.